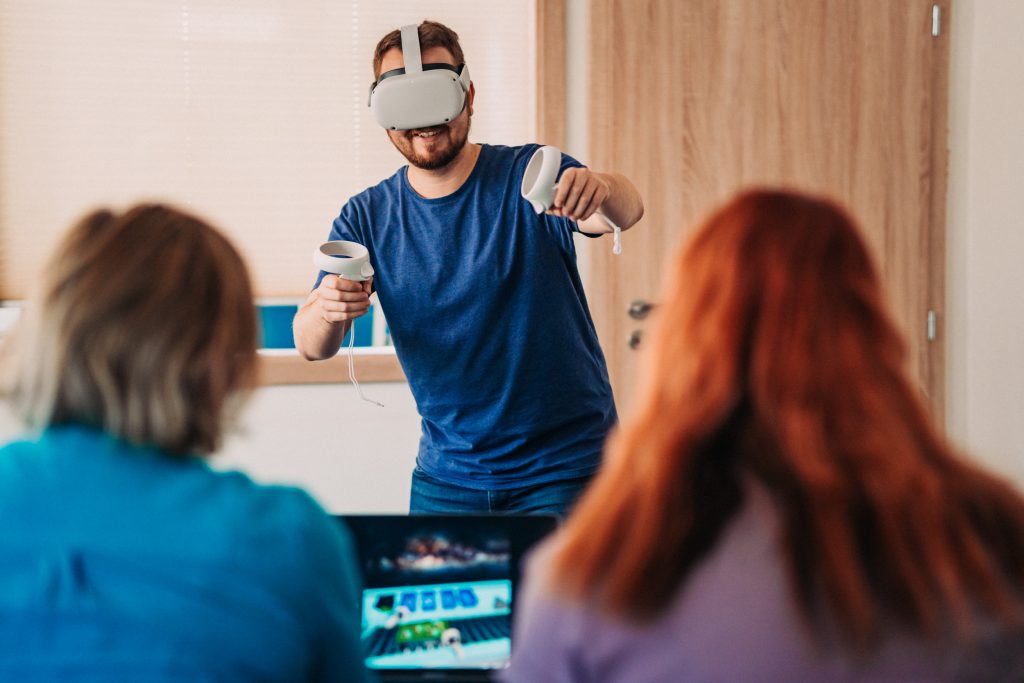

Real training in virtual world

We provide virtual reality training for companies, schools and also individuals.

Benefits of VR education

34 % more effective than traditional teaching

56% shorter learning time

68% lower costs and environmental impact

84% fewer accidents

Source: PWC – Effectiveness of Virtual Reality Soft Skills Training in the Enterprise 2019

VR Testing

We will help with the selection of suitable candidates for manual professions by testing their attention, observation and dexterity.

- Reduces costs of employee turnover

- High quality and fast selection of employees

- Time efficient testing and evaluation

- Immediate feedback

- Making recruitment more attractive

Coating

Effective and safe training for painters. Simspray helps you step by step to master wet and powder coating or blasting.

- lower training costs

- faster learning

- saves the environment

- no emissions and material loss

- immediate analysis and feedback

HSE training (Health and safety training)

Firefighting, first aid and simulating hazardous situations in a safe VR environment.

- A realistic experience of hazardous situations will show everyone that following workplace safety rules is a must

- Reinforces the effectiveness of safety training

Welding

Real welding training in virtual reality

- Used by more than 75 countries worldwide

- Easy to use

- Use of real welding helmet, realistic use of welding machines

- Joing welding mode

Soft skills

Training in negotiation, public speaking, presentation, business and other skills

- Provides the authentic experience needed to develop soft skills

- Affordable

- Has an absolute learning effect and immediate applicability in practice

- Measures improvement in the skills being trained

- Increases workforce competency

Tailored product development

Training in service and operation of machines and equipment, including training of new employees.

Practical implementation of a specific production or work process in a simulated reality, copying the work environment.

- Training in VR protects expensive production technology from potential damage during training.

- No work interruptions in continuous production environments

- Saves time for experts to train new workers

- Reduced scrap and material costs